Traceability - something you should not miss

Traceability of material history (in English: Traceability) generally means that for the product delivered can be found at any time when, where and by whom was the product manufactured. In our case, this means that we know about all active items obtained in the product from our system to identify the producer and his production batch. In this way we can find out the cause which has influenced functionality of the product. This can be very important in determining responsibility for damages. I is also helpful when it is necessary to find the cause of a malfunction or failure of the products.

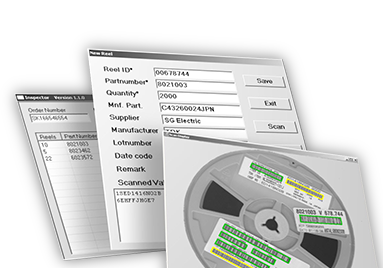

Each material on our store has special label. This label contains all necessary traceability data :

- Name and case description

- art.nr. in our ERP system

- date of income on our store (useful for FIFO store management )

- number of incoming document

- position on the store

- LOT- production batch number of producer

Traceability data are scanned from the store labels by issue of material for production. These data are then stored to each production batch in our ERP system. Each our product has LOT label and according to this we can find out these data later in our system. We use matrix code for scanning data from the label. This makes the work more fluent and quick and eliminates the errors which could occur by hand recording.