Testing - for maximum reliability

Thanks to continuous production tests and final inspections, we guarantee a lasting high quality. In repeating customer orders a consistent product quality is guaranteed.

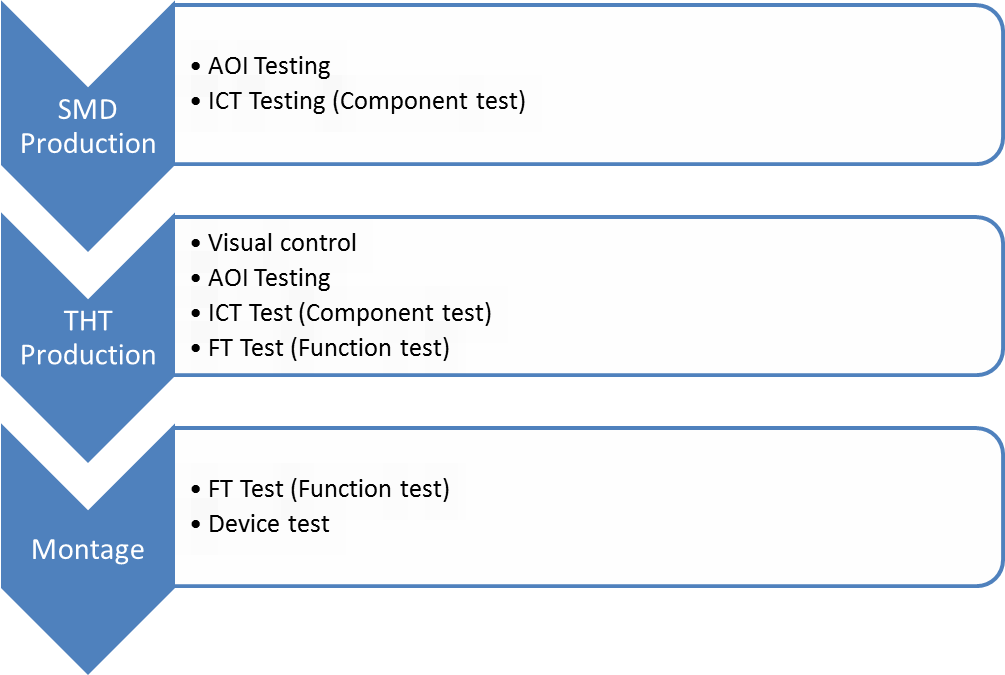

Depending on the technological points in the production, this control is divided in:

- mechanical control

- optical control

- AOI inspection

- ICT test

- function test

- statistic control

AOI Inspection

Kohyong Zenith 3D AOI - Revolutionary New 3D Measurement

Most modern 3D-AOI-Tester of new Generation

- SMD inspection

- Dramatical improvement of AOI inspection

- reduction of pseudo errors

- True Measurement of the 3rd Dimension

- Flags and Quantifies All Defects

- Intuitive Programing Using 3D Measurement

- Total IPC 610 Compliance Solution

- The Perfect Warp Compensation Solution

Two AOI testers for THT Inspection

Göpel Opticon Basic Line

Maximum error recognition thanks to:

- Unique multi spectrum lighting: from infrared to ultraviolet

- Patented 360 ° -Inspection in 1 ° increments with constant resolution and sharpness

- Program optimization based statistically recorded inspection data

- repair station

Marantz M22XDL 350

- the AOI test device

- used for THT and SMD control

- flexible and reliable testing

- Program optimization based statistically on recorded inspection data

- repair station

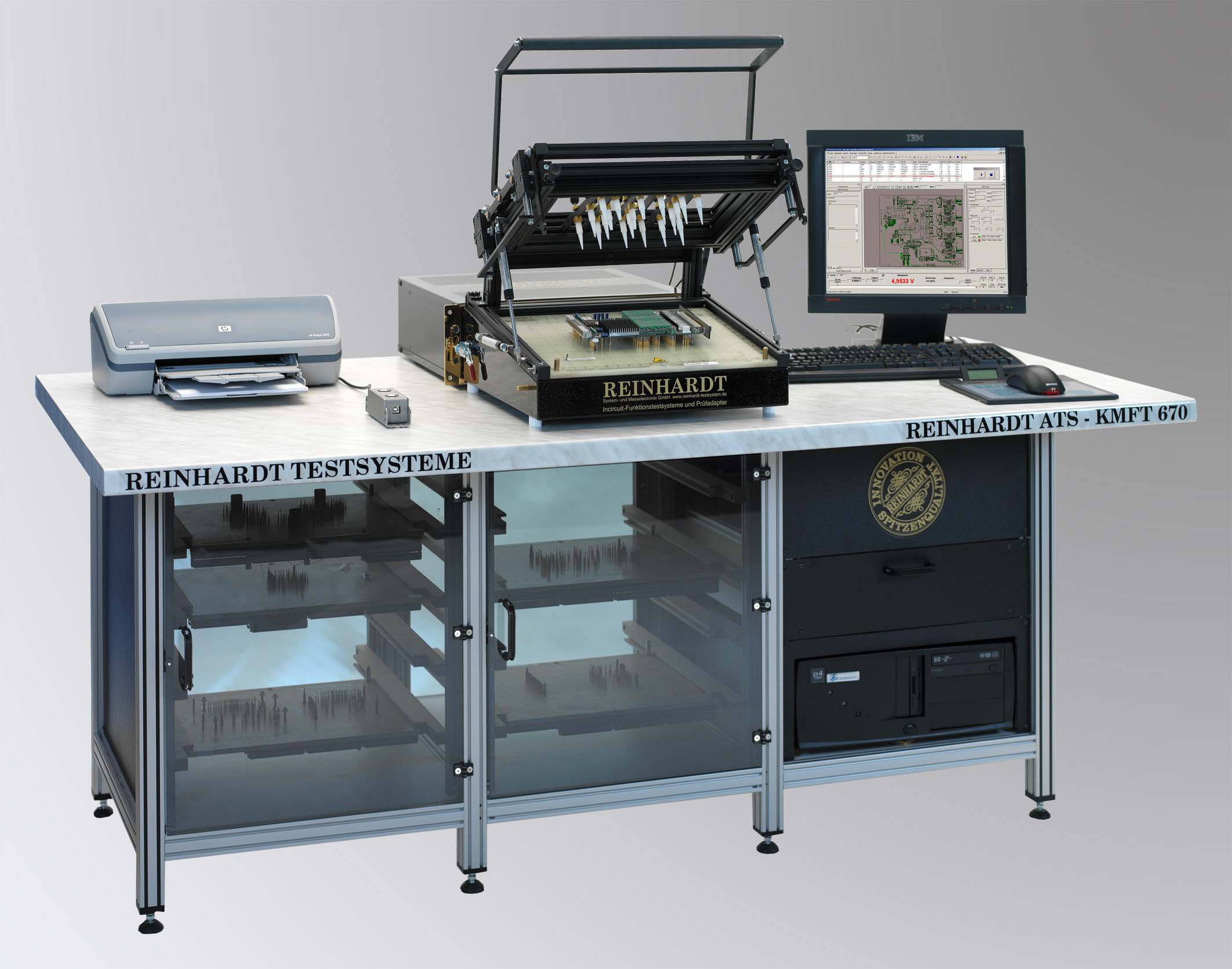

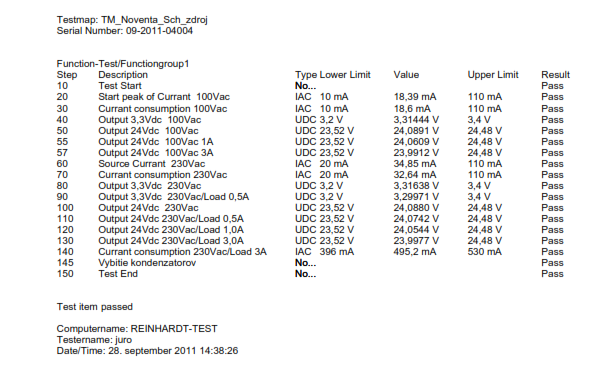

ICT and FT Testing

- Two test devices Reinhardt allow ICT and function testing

- We prepare the testing according to the customer specification

Storing of the testrun-protocol

- by each ICT and function test on the Reinhardt tester we store the test run sequence

- Test sequence is stored according to the serial number of the tested item

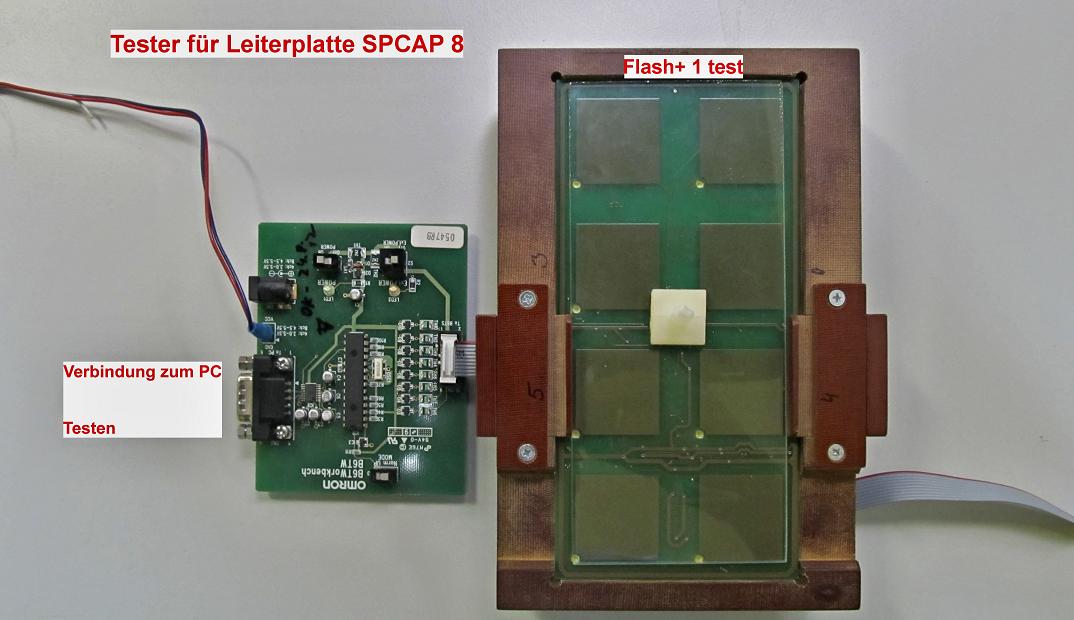

Mono functional test devices

In addition to these test devices we use mono functional test devices according to the requirements of our customers.

Eurotron component a.s. © 2013

...try our quality